A dynamic piece of steel, Damascus has an etched texture that sets it apart and distinguishes it. While it is impossible to replicate the original Damascus steel as it was known many centuries ago, it is possible to generate a robust alloy with a pattern that is close.

This technique is frequently used to manufacture knives and other blades. It is among the most exquisite pieces of blacksmithing, nevertheless.

The good news is that it’s not as tough as it first seems to learn how to forge Damascus steel.

Here is an article that will teach you how to forge Damascus steel quickly and easily.

History of Wootz Damascus Steel

The term “Damascus,” which has its roots in medieval western civilizations, describes an older aesthetic of workmanship that initially appeared in India about 300 B.C. Around that time, Wootz steel was brought by Arab culture to the Syrian city of Damascus, where it sparked a booming armaments industry.

To produce and use hybrid steel blades noted for their tenacity, Damascus obtained Wootz steel from Persia and Sri Lanka.

It appears that individuals responsible for this technical advancement realized that mixing several metals would result in weapons that were stronger than those fashioned of pure steel.

Due to their distinctive methods of steel manufacture, the native bladesmiths in the city of Damascus were recognized as the best in the world more than a thousand years ago.

The Damascus pattern has several bands and mottling that are pattern-welded steel together to form beautiful blades of any shape and/or length that are unbreakable.

Since there are no documents describing the composites in the real Damascus steel, their identity is still unclear today.

In terms of history, the Damascus blade has acquired a somewhat ambiguous reputation due to the disappearance of early references about 1700 A.D., which coincided with the fall of pattern swords and the eventual end of manufacture some fifty years later.

But Damascus-style steel’s long history and importance have never been lost, leading to the current thriving business.

Damascus Steel: What is It?

A special kind of steel called Damascus steel has alternating light and dark grains that produce interesting trends and a high carbon concentration.

Today, two distinct sheets of steel are combined into a single design by blacksmiths and knifemakers utilizing a pattern welding procedure.

The commercially accessible high-carbon steels used in modern Damascus steel, such as 15n20, are deliberately combined with metals like nickel and vanadium to produce certain qualities.

This all-encompassing strategy has produced varieties that are as distinct as they are lovely.

Different Types of Damascus Steel

Cast Damascus steel and pattern-welded Damascus steel are the 2 types of steel.

Forged Steel

Cast wootz steel was created by melting iron, steel, and charcoal in the presence of little to no oxygen to create cast wootz steel. In these circumstances, the metal took up carbon from the charcoal.

The alloy produced a crystalline substance that included carbide after slow cooling. Forging wootz into swords and other items produced Damascus steel.

Pattern-weld Steel

Knives and other contemporary items manufactured with pattern-welded Damascus steel have many of the same qualities as the original Damascus metal, including the watery pattern running through the whole piece of metal.

Iron and steel are layered, then the metals are forged together by hammering at a high temperature to create a welded bond. This process is used to create pattern-welded steel.

To keep oxygen out of the joint, a flux seals it.

How to Make Damascus Steel?

Although the process of forming Damascus steel blades is straightforward, it nonetheless calls for constant attention to detail. The procedure takes time, nonetheless. This is required to achieve the appropriate aesthetics and to create a powerful, well-balanced blade.

Some necessary ingredients are often needed while forging Damascus steel. It would be preferable if you had particular tools in addition to the materials needed for formation. The required tools and materials for performing this forging process include-

- Forge

- Anvil

- Hammer

- Tongs

- Tempered air oven

- Drill press/drilling

- Vise

- Welder

The Process to Forge Damascus Steel

The following steps are how to form your Damascus steel

1. Obtain the Materials and Tools

The process of forging Damascus steel begins with this. Your materials must be accessible at all times for the procedure to succeed. Before beginning the process, make sure the necessary supplies are nearby.

1.2. Assemble the Specialist Steel-forging Materials.

This is the next step to assemble materials, such as glass or fine silica sand, ferric chloride, metal debris, brass pins, rebar, quenching oil, and a polishing media in addition to the equipment mentioned above.

2. Cut and Allign The Steel Billets

It’s time to increase the number of layers of steel at this point. Make careful to hammer the billet from all sides so that you extend it rather than merely spreading it out.

To create your Damascus steel, you must combine billets of steel. Billets of Damascus must first be assembled as they are sent to you as separate objects.

Making Damascus steel requires cutting the materials to the desired dimension. But it’s advisable to cut your billets into enormous sizes.

3. Hammer the Steel

Due to how much the size of the billets will affect the procedure, the cutting requires exact dimensions.

The more substantial the billets, the simpler it is to hammer the Damascus steel into shape. To get a clean forge, make sure the metal has been properly descaled and oxidized.

4. The Heating Process of the Blade

The welding temperature range for Damascus steel, around 1500 and 2000°F, should be reached in your forge. The billets should be placed in the forge and kept there until they start to flame red.

Then, whereas the steel is still hot and blazing, shape it. Withdraw the metal from the forge as it reaches the required temperature, then shape the steel with the hammer it into the desired form.

Based on the kind of Damascus steel you’re trying to make, the temperature may change. It could also vary on the sort of steel you’re working with. The general procedures for heating Damascus steel are as follows:

- Set the temperature of your furnace to an appropriate level (often between 1500- and 2000 degrees Fahrenheit). Find a means to gauge the temperature and make sure it falls within the appropriate range.

- Place the completed billet block inside the forge to heat, then leave it there for a while.

- Weld the billet until it turns cherry red.

- To have a clean welding process, keep air away from the metal to avoid corrosion.

- Before removing the steel, watch it warm up to the proper temperature.

- Till the temperature returns to normal, quickly cool in water or cooling oil for around ten minutes.

- Alternatively, you might first soak it in water before quenching it in blacksmith’s oil.

- Depending on the kind of Damascus steel you want to make, repeat this process 2–3 times.

- The procedure is finished by passing the iron into liquid hydrogen for roughly an hour.

4.1. Heat the Blade at 350–450 °f

By putting the steel in a temperature-controlled forge, you can maintain this temperature for nearly an hour before letting it cool. In order to harden the steel, repeat this procedure a few times.

The temperature is often accurately regulated for tempering. You might not get the desired outcome if you don’t carry out this operation at the right temperature.

5. Etch

This is the final and frequently defining phase in the initial weld of Damascus steel. Typically, the etching and finishing processes go hand in hand like a ring on a finger.

- Finish the steel surface with grit.

- As directed by the manufacturer, dilute your ferric acid. Steel was immersed in the diluted solution for a predetermined amount of time.

- The manufacturer’s instructions often provide the recommended immersion periods.

- After washing the steel with clean water, allow it to air dry.

- Repeat the immersion process in 5-7 minutes.

- After getting the required results, neutralizing the steel by passing it all through trisodium phosphate is an option.

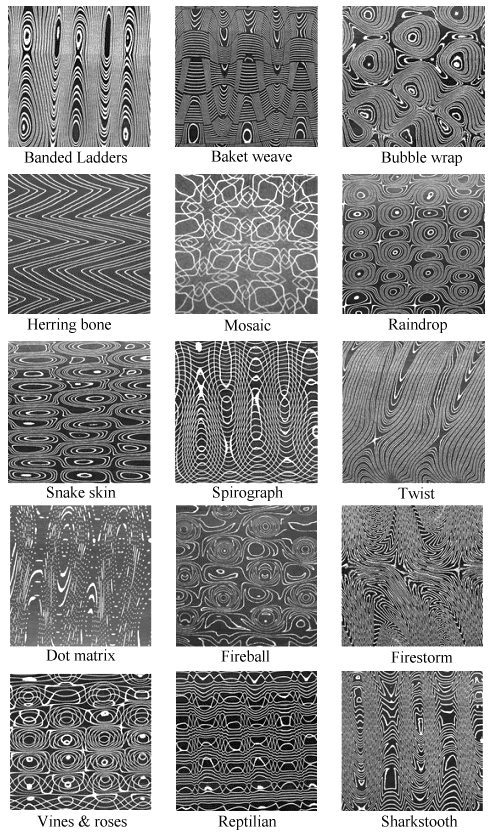

Damascus Steel Patterns Guide

Damascus steel is a type of forged steel that has distinctive patterns on its surface. It is made by combining different types of steel and applying various techniques to create different designs.

Random pattern: This is the classic Damascus steel pattern that looks like flowing waves or ripples. It is created by forge-welding multiple layers of steel and then forging and grinding the billet into a blade shape. The random pattern emerges as a result of the distortion of the layers during the forging process.

Twist pattern: This pattern looks like spirals or stars on the blade. It is created by forge-welding a square bar of layered steel and then twisting it along its axis. The twisting can be tight or loose, depending on the desired effect. The twist pattern is more visible when the blade is ground deeper.

Ladder pattern: This pattern resembles parallel lines or rungs across the blade. It is created by pressing or grinding grooves across a Damascus bar and then forging it into a blade shape. The grooves create contrast between the layers and form the ladder design.

Raindrop pattern: This pattern looks like drops of water or bull’s-eyes on the blade. It is created by pressing or drilling dimples into a Damascus bar and then forging it into a blade shape. The dimples create circular patterns that resemble raindrops.

Hydraulic Press Vs. Power Hammer

Power Hammer

Power hammers, which have been used in a great deal for Damascus steel forging, represent the classic bladesmith instrument.

Hydraulic Press

Compared to a power hammer, the hydraulic press has a number of benefits. For the novice, the press is considerably simpler to use, and dies may be created for the press that completely encloses the billet, simplifying the forge weld.

Damascus Steel Knives

The strength and durability of ancient Damascus steel were its most well-known qualities. It was created in the Near East utilizing Wootz steel from ancient India.

This type of steel is distinguished by the presence of “carbides,” which are carbon steel that runs throughout the steel.

Analysis of historical Damascus steel blades reveals that specific impurities added during manufacturing strengthened the metal and increased its flexibility and toughness.

There are several different types of Damascus steel knives available for a wide range of uses, including camping, survival, wood-cutting, and hunting.

The composites that are joined to form a Damascus knife must take into account both the type of knife and the situation in which it will be used.

How to Make a Damascus Knife?

A process for creating a Damascus steel knife with a surface pattern in which an ingot is formed from a steel melt containing between 1.0 and 2.0 weight percent carbon and is then heated between 1095 and 1299 degrees Celsius.

A malleable envelope is created around the steel ingot for a period of time between 5 and 12 hours, either separately or in conjunction with the heat treatment.

FAQ’s

Is Damascus steel suitable for making knives?

Most expensive Damascus special steel kitchen knives are renowned for their fine edge maintenance and sharp cutting.

What is used to forge Damascus steel?

Damascus steel also can be made with a variety of steel. However, the two most important materials to use are high-carbon steel and stainless steel, or a mix of both.

How much do Damascus steel knives cost?

They are clearly not worth the additional money, and normal modern kitchen knives of moderate to decent quality easily exceed them in terms of performance.

Can a fake Damascus knife exist?

A false Damascus knife may be identified by careful inspection. Unnatural patterns, such as not folded, wavy, twisting, raindrop, generally watery, and feather patterns, will be present on a false Damascus knife.

Hi, my name is Taras Kulakov and I’m a knife enthusiast. I have been collecting knives for over 30 years and I’ve owned literally thousands of different models over that time. My goal with this site is to share some of what I’ve learned about knives. You can find more info about Taras Kulakov here.