Damascus steel, a steel that looks like something straight out of Westeros on “Game of Thrones,” but this beautifully swirling pattern blade which is known as the damascene pattern has a more earthly origin.

The exquisite look and the unique features of this steel made it sought after in its prime time.

Prized for centuries, Damascus steel lost prominence by the 18th century but today it’s made a resurgence. So what is this mythical steel? Read on to know everything you need to know about Damascus Steel.

What is Damascus steel?

The fabled Damascus steel, also known as Damascened steel and sometimes watered steel, is mostly known for the steel that is used in custom knife and sword making. It’s now commonly referred to as two types of steel; pattern-welded steel which gives the original appearance of Damascus steel and wootz Damascus steel which is the epitome of sharpness and strength.

The method of forging this legendary steel has been lost to time. Both types of Damascened steel show complex patterns on the surface, resulting from internal structural elements in the steel.

This unique forging technique was guarded by a selected few but yet feared lost to history. But fortunately for professional, modern technology and metallurgical science has advanced enough for scientists to discover modern ways to recreate the resilient and exquisitely intricate ancient Damascus steel.

Re-invention Of Damascus Steel

In the early centuries of Damascus steel, its most common use was for weapons. That is why it was so prized. Back then Swords were difficult to make because they are long and slender. So they needed the best steel to make them stable and flexible. Damascus swords were reliable and earned good fame pretty quickly.

Although Damascus steel was named after what is now the capital city of Syria it was most likely developed in several locations. Damascus pattern was originally an undocumented forging technique utilized by Near East and Middle Eastern sword makers. Some version of Damascus steel blade has been produced for centuries, everywhere from Indonesia to the Middle East.

During the Crusades of the 11th Century, Western Europe received its first real taste of the Damascus pattern. The Crusaders witnessed the infamous Damascus steel sword’s unequivocal sharpness in action at the hands of the Arab warriors. The ferocity of those Arab warriors with their unique blades caught the eyes of the leaders. The goodness of Damascus’s sword gave rise to the legends which spread throughout the Middle East and Europe.

Traditional true Damascus steel is easily recognizable by its multiple swirling patterns on the flat of the blade. The unique patterns are originally from Indian and Sri Lankan wootz steel. Wootz steel ingots contained a variety of “impurities” such as tungsten and vanadium. Combing them with the traditional Indian smelting process and numerous rounds of layering are used to prepare each blade. That’s how the magnificent original Damascus steel blades were created.

The Arabs successfully imported the wootz steel ingots for centuries. Verhoeven and his co-authors explain in their study that both patterns welded steel and wootz Damascus were being produced by the sixth century. The weapons made from these steels were lightweight, strong, and durable. They had great edge retention and stayed sharp even after being used in battle. It was even said that blades made of wootz steel could cut through a silk scarf as it fell.

But the forging process for wootz Damascus has been lost to history as borders altered, wars ravaged and wootz reserves ran dry. Slowly the world began to lose touch with the masters of this unparalleled Damascus steel.

By the early 19th century, the production of this steel was fully stopped. Partly because the metalsmiths who made it kept some of the damascene pattern secrets.

But then again there are different traditions from different countries or different regions of forging steel. Damascus isn’t one specific formula.

By the late 1800s, modern metallurgy had improved the quality of steel. Even the pattern welded Damascus steel was produced at that time. But unfortunately, it became obsolete and got a very bad reputation. Modern steel simply worked better than its forbears. And today, the ramification of modern Damascus steel plays second fiddle to its good looks.

A Modern-Day Reinvention

The human race is nothing but nostalgic and supreme. Thankfully, historians, collectors, and metallurgists from all over the world accompanied and improved technologies to re-engineer the Damascus steel forging process. But of course, they have added a modern touch to it.

September 29, 1981, a New York Times article revealed that two Stanford University scientists researching metals with superplastic characteristics accidentally recovered the secret to creating Damascus steel.

From their research, they have found out that the steel which is used to create the ancient blades required high carbon steel and a relatively low temperature for the forging and hammering process with a rapid rise in heat followed by a swift. The “quenching” or cooling process for ancient Damascus steel blades is fodder for tall tales.

The quenching process is where the blades achieved their magical strength. The leaders believed that the forgers used to thrust the heated original Damascus blades into slaves to transfer their strength into the blade, or that the blades were “quenched” in dragon’s blood.

Of course, it’d be ridiculous to believe that the blood had something to do with the strength but some modern scientists think the nitrogen in the blood may, in fact, have strengthened the alloy.

Damascus steel is not a pure metal. It relies on a variety of impurities. The steel is also imbued with high carbon percentages to provide beauty, strength, and durability.

All these are paving the way for the modern Damascus steel revival. The plasticity of the heated metal and the durability of the cooled product allows this steel to be shaped into a wide variety of tools, from gears and auto parts to fashionable styled, high-end kitchen knives.

The Beauty of Modern Damascus Steel

Modern buyers seek out Damascus steel for the aesthetic mostly rather than function. With the improvement of modern technology, there is now so many version of Damascus steel. When it comes to swords and knives, some people reach out for the appearance than the medieval purposes.

With the first pace of modern technology, now you will get to see various types of Damascus Steel. Some true artists managed to create designer pieces of this steel. Other steelmakers are more interested in maa production. The higher volume and repetition of a specific Damascus blade is seen mostly in the market.

Conventionally while making steel, the solid pieces are forged together. But Damasteel makes stainless Damascus pattern weld through powder metallurgy. Working with two grades of steel for color variation, Damasteel creates a “recipe” for a pattern and can repeat it.

Some patterns are trade secrets, and others are just difficult to replicate. There are similar patterns that multiple blacksmiths make, although they might have different names. What one smith calls a Rose pattern, another may call a Raindrop, for example.

If the pattern names sound too delicate for the nature of the business, there are other options too. Damasteel has patterns called Thor, Odins Eye, Loki, Bifrost, and Bluetongue. Or consider Snakeskin, Razor Wire, and Fireball from Devin Thomas. What they all have in common is a quality of beauty.

Specification of Damascus Steel

From selecting the proper steel with the proper alloy and carbon content to forging and quenching the steel, the creation of modern Damascus steel is an artwork. The process is extensive and precise.

For instance, F.N sharp combines VG10 and VG2 steel to manufacture a feathered Damascus Pattern. VG10 contains roughly 1% carbon and molybdenum, 15% chromium, 1.5% cobalt, and less than 1% vanadium, manganese, and phosphorus, while VG2 is comprised of roughly 1% carbon, 15% chromium, and less than 1% copper, molybdenum and nickel. To make the steel a bit darker Manganese is added to VG10 and nickel is added to VG2 to produce bright silver-tone steel.

The differing elements of steel also have different purposes. For example, the addition of carbon improves a blade’s hardness, edge retention, tensile strength, and resistance to wear and abrasion, while the addition of manganese improves grain structure, hardenability, strength, and wear resistance.

The addition of chromium, which is one of the most important elements of stainless steel (at least 13% chromium is required for stainless steel) improves harness, tensile strength, and resistance to wear and corrosion.

To create Damascus, two sheets of steel need to be stacked into alternating layers. And then when a billet is created, it needs to be twisted, folded, and then heated, hammered.

When the billets are folded and hammered and the hot metal turned into the perfect shade of dark red (light red means the temperature is too high and the metal will crack), the steel is then quenched to harden the temperature.

Finally, the shaping process is finished by hammering, lengthening, and flattering the metal until a unique pattern of Damascus steel is revealed.

Damascus Steel Equivalent

Damascus steel is known as a “Super Steel”. It is a high-end steel alloy with a unique chemical composition. Let’s look at how Damascus steel compares with other types of steel, in the areas of toughness, edge retention, corrosion resistance, and sharpness. I use a scale or note from 1 to 10 with 10 being the best possible grade.

Damascus Steel VS Carbon Steel

| Attributes | Carbon Steel | Damascus Steel |

| Toughness | 7.5/10 | 9/10 |

| Easy sharpening | 7/10 | 7/10 |

| Edge Retention

| 7/10 | 9/10 |

| Corrosion Resistance | 3/10 | 4/10 |

Damascus steel made with carbon steel produces the best type of steel for knives.

Damascus Steel Vs D2

| Attributes | D2 | Damascus Steel |

| Toughness | 6/10 | 9/10 |

| Easy sharpening | 4/10 | 7/10 |

| Edge Retention

| 3.5/10 | 9/10 |

| Corrosion Resistance | 4/10 | 4/10 |

In the case of edge retention and toughness, Damascus performs better than D2.

Damascus vs VG10

| Attributes | VG10 | Damascus |

| Toughness | 4/10 | 6.7/10 |

| Easy sharpening | 6/10 | 8/10 |

| Edge Retention

| 5/10 | 9/10 |

| Corrosion Resistance | 7/10 | 6/10 |

Damascus steel made from VG10 makes premium-quality knives.

Types of Steel Used to Make Damascus Knives

Depending on the purpose of the blade, the steel required to forge Damascus steel might vary. High carbon steel, stainless steel, or a combination of both are the primary requirements. High carbon steel blades are renowned for their sharp edges, while stainless steel blades are known for being impervious to oxidation. Some commonly used steel grades include VG1, VG2, VG10, AUS8, and AUS10.

VG1: Is primarily stainless steel with higher carbon content than other VG series steel. This Japanese steel is produced by Takefu Special Steel Company. This steel was the antecedent to VG10. It holds a greater edge and is very popular for being sharp. If you look at the chemical composition of this steel, it has lackings of cobalt and vanadium. So blades made from this steel are highly likely to chipping and corrosion.

VG2: Another one from Takefu Special Steel Company creation. This hard stainless steel has a rockwell hardness of 62. Although it has lower carbon content than VG1 and VG10, higher in other metals such as chromium, nickel, and copper makes it a top-class corrosive-resistant blade.

VG10: Is my personal steel for a knife blade. It’s a famed Japanese stainless steel also by Takefu Special Steel Company. This steel is known for holding edge frighteningly. It’s very strong steel, super sharp, and durable. It has higher carbon content, with the combination of specific series of other metals. The presence of Cobalt, carbon, chromium in this steel keeps it free from oxidation and very hard. The rockwell hardness of this steel is 60-62. It’s the best steel to make kitchen knives.

AUS8: Is Japanese steel produced by Aichi Foundry. This steel has a high carbon content that is needed to produce a hard knife but is known for requiring frequent sharpening. This stainless steel is considered to be mid-level steel if it is compared to the superior VG10 or AUS10. Because of the edge retention issue of the steel, knives made from this steel are not as premium as knives forged of VG10 or AUS10. This allows for knives of this steel to be more affordable and easily mass-produced.

AUS10: Is Japanese steel produced by Aichi Foundry. The Rockwell hardness of this steel is 58-60. It has better edge retention than AUS8. AUS10 is similar to VG10 which is commonly great for knives and used to produce premium high-end kitchen knives.

VG2 and VG10 steel to create exceptionally sharp and stunningly beautiful Damascus steel kitchen knives, from the powerhouse chef’s knife to the handy little paring knife and even steak knives, too!

Is Damascus steel good for kitchen knives?

The strength of any Damascus steel knives totally depends on the steel which is used to forge the blade. Quality Damascus steel will provide an aesthetic piece with a unique and intricate design as well as a very long-lasting sharp edge and strong blade, with greater rust resistance.

Usually, Carbon steel is what knife makers prefer if they want to produce hard and durable knives. The carbon amounts in VG10, VG1, AUS8, AUS10 is precise that’s why knife made with these steel alloys are softer to work with and again has greater rockwell scale than regular stainless steel.

Damascus kitchen knives have been making their way into the home kitchens of most knife enthusiasts across the globe. The lovely damascene pattern makes them an art piece for the kitchen.

Depending on the steel used to create it, Damascus steel provides the perfect ratio of carbon and trace elements of stainless steel to offer the perfect balance of ductility, corrosion resistance, and sharpness – key to any chef’s requirement for versatility with a knife.

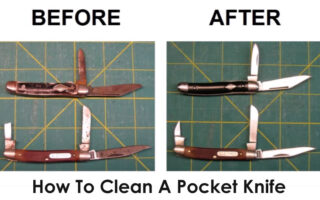

Damascus steel maintenance

If you are worried about the longevity of your Damascus knife, simply follow the guideline that is provided by the manufacturer. Taking care of Damascus is no different than other knife steel.

Due to having weak rust-resistant, it’s important to quickly wash the knife and pat it dries with a towel after each use. Thus, you will remove any sort of organic material that would layer on the blade and degrade the steel.

If you own a carbon Damascus steel blade, it’s important to dry the excess water before keeping it in a drawer or other knife storage box. You may also need to sharpen the knife once every two months. Polish the knife once a month to keep the intricate design and shine of the knife intact.

Use a non-abrasive polishing cloth weekly. If the blade is for decorating purpose, oiling it regularly will keep a bright sheen and enhance the beautiful Damascus pattern.

If you are into a more basic knife with lower maintenance, Damascus steel made from stainless steel would be the best option for you. As those are more likely to have greater corrosion resistance. Stainless steel Damascus is much easier to maintain.

King of the kitchen knives?

Damascus steel has grown from stunningly terrifying blades of Moorish legend to a highly versatile material with endless applications.

A growing number of professional chefs are choosing Damascus due to the strength and longevity of these blades. Forged using the Damascus steel techniques, the knives are considered to be premium kitchen knives.

The remarkably sharp edge of the Damascus knives makes them the king of all kitchen knives. However, It could be a little difficult for a novice to sharpen the knife perfectly. Allowing an expert to sharpen your Damascus steel knives will ensure they last for years to come.

Damascus steel knives are all the rage in kitchen cutlery these days. There is some validity to the appearance and functionality of these blades.

FAQ:

Top 3 Damascus chef knives are:

8″ VG10 Damascus Steel Chef Knife w/ Included Sheath.

Enso SG2 Japanese Gyuto Damascus Stainless Steel 8″ Chef’s Knife – Highest Quality SG2 Blade.

Mikoto 8″ Gyuto Japanese Damascus Steel Chef Knife w/ Hammer Finish – Best Damascus Blade w/ Hammered Finish.

What is so special about Damascus steel?

Most people are familiar with Damascus steel and know that it has a beautiful, wavy pattern. However, most people don’t know that Damascus steel is even more valuable than regular steel. The reason is because it’s both hard and flexible while also maintaining sharp edges. Knives forged from this type of steel were much better than those forged from other material.

Is Damascus steel stronger than normal steel?

The Damascus steel is not the strongest metal that you can find. However, it has been proven to be strong enough for most projects and uses. There are some modern alloys of metals that are very strong and durable and if you’re working on a project that has to withstand harsh conditions then you should use one of those. The Damascus steel is usually used for making hunting knives, golf clubs heads or firearm components which proves to be more than enough for it.

Why do they call it Damascus steel?

Damascus steel is a type of steel that is named after Damascus, the capital city of Syria and one of the largest cities in the ancient Levant.

Does Damascus steel rust?

Damascus steel is not immune to rust. It’s still sturdy and durable, but like any other form of steel, it will rust. The good news is that caring for your damascus steel knife is also easy since all you need to do is just keep it dry. The two main enemies are moisture and time, so make sure you don’t leave your blade wet for too long.

Hi, my name is Taras Kulakov and I’m a knife enthusiast. I have been collecting knives for over 30 years and I’ve owned literally thousands of different models over that time. My goal with this site is to share some of what I’ve learned about knives. You can find more info about Taras Kulakov here.

![What Are The Top American Made Knives? [Best Knife Makers] 7 What Are The Top American Made Knives](https://knivesngear.com/wp-content/uploads/2022/11/What-Are-The-Top-American-Made-Knives-320x200.jpg)

Wow! I never knew that the forging process of Damascus steel had been lost to history. Thanks for sharing such an informative post. It’s fascinating to learn that modern technology has enabled scientists to recreate this ancient steel. I think it’s amazing that this metal was so prized for its durability and strength, and that its unique patterns make it a popular choice for custom knife and sword making today. It’s interesting to think about how the ancient methods of creating Damascus steel compare to the modern-day reinvention.